Solution

Zhengye Technology Introduces Battery Automatic Traceability Laser Marking Machine

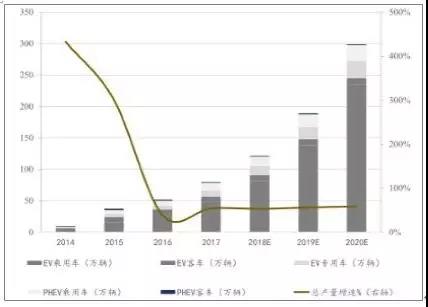

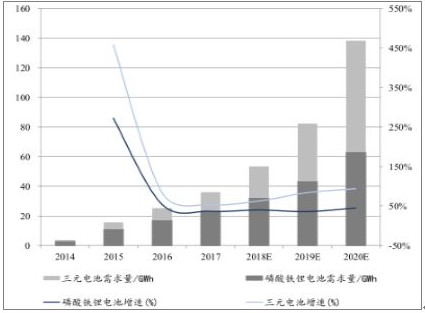

The battery involves all aspects of life. From small watches and smart phones to computers and household appliances, batteries are needed. Even new energy vehicles that are currently on the market and driven by powered lithium batteries have become an important part of people's lives. One of the consumer goods. The National 13th Five-Year Plan proposes that by 2020, the sales of new energy vehicles will reach 2 million. Driven by various national policies, the production and sales volume of domestic new energy vehicles has hit record highs, and it has also brought about explosive growth in the power lithium battery industry.

With the increase in the demand for batteries, if the manufacturer wants to ensure a large number of stable shipments, it can control the information of raw materials, product batches, product destinations, production quality and other information to achieve intelligent traceability, which requires a new process. - Laser marking and intelligent traceability technology to solve.

Battery automatic trace laser marking machine

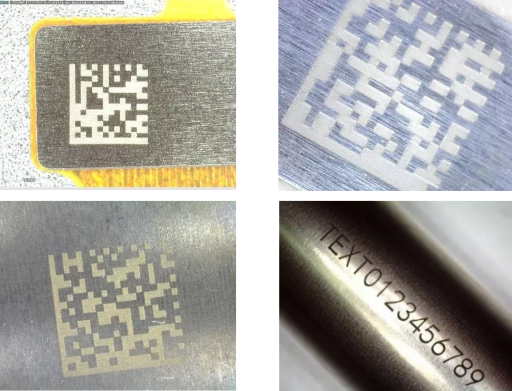

Zhengye Technology has developed an innovative product--Automatic Battery Tracking Laser Marking Machine, which is used in various battery production industries; it is mainly used for automatic laser marking of battery material surface, which can be used in aluminum, aluminum alloy, stainless steel, etc. Automatic laser marking of metal and alloy surfaces. The raw material information, production process and process, product batch, manufacturer, production date, product destination and other information can be automatically generated into two-dimensional code, through laser automatic processing on the surface of the material, real-time docking MES / ERP system, etc., to achieve product Traceability and full lifecycle management.

Compared with traditional printing technology, laser marking has the characteristics of good quality, high consistency, strong wear resistance, high efficiency, cost saving, safety and reliability, and is widely used in various battery production industries.

Product advantages:

Automatic rewinding, automatic marking and intelligent tracking, realizing life cycle management of products

With imported lasers, stable performance

High-speed laser system, high processing precision, fast speed and stable performance

User-friendly software interface, easy to learn and powerful editing

Automatically obtain information such as work order number, product batch number, material code, product name specification, etc.

It can automatically read the QR code and save the data. It can automatically record and alarm when it cannot be read.

Real-time monitoring of MES/ERP for real-time monitoring and intelligent product traceability

No consumables, environmental protection, no pollution, maintenance free.

Sample effect:

Technical Parameters: