Solution

How do FPC Companies Choose Cost-Effective Drilling Machines?

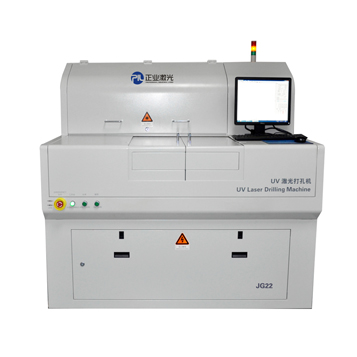

1. Laser Drilling Machine quality and efficiency

The EST Drilling Machine focuses on improving the efficiency and quality of blind hole drilling through holes of 35 microns and above.

In the design with dense micropores, for example, the 250mm*300mm board is distributed with 14000 porous design. This model is conservatively estimated to increase the hole drilling efficiency by more than 20% compared with the imported model, and double the blind hole efficiency.

2. Purchase cost

The core hardware of EST drilling machine adopts the best industrial brands in Europe and America. Its hardware cost is not less than that of other brand equipment. In the field of overall equipment system integration, Wuhan Yukesai technical team is better; we are working hard in management. To improve the efficiency of the company's operations, save costs, and reduce the operating and management costs of the company, so that the company's equipment has a procurement cost advantage.

3. Comprehensive cost analysis

The comprehensive cost of UV Laser Drilling Machine should be comprehensively determined by factors such as equipment procurement cost, equipment operation and maintenance cost, and equipment drilling efficiency.