Solution

Common Methods for Failure Analysis of PCB Boards

Due to cost and material changes, PCBs have experienced a large number of failures during production and application. How to deal with product failures has become a top priority for users.

Failure analysis can help users:

1) Find out the cause of the product failure;

2) Tracking the undesirable factors in the design, manufacture and use of the product;

3) Propose corrective measures to prevent recurrence of failure.

Between the structural characteristics of pcb and the main mode of failure, Xiaobian will focus on six basic methods for pcb failure analysis:

1) Visual inspection

2) x-ray fluoroscopy

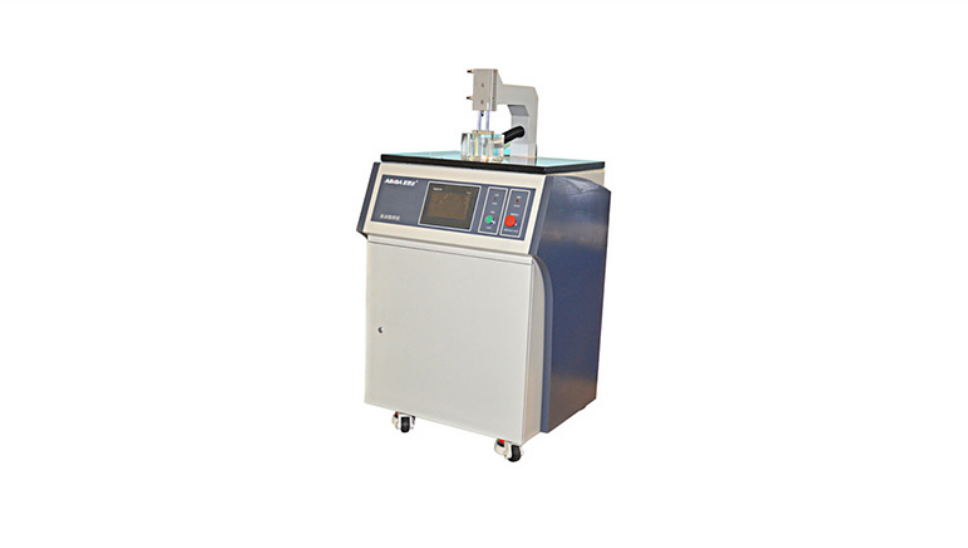

3) Metallographic section analysis by MetalLographic Sample Cutting Machine

4) Infrared microscope analysis

5) Scanning acoustic microscopy analysis

6) Energy spectrum analysis

The slice analysis by MetalLographic Specimen Preparation Machine is a process of obtaining a cross-sectional structure of a PCB by a series of means and steps such as sampling, inlaying, slicing, polishing, etching, and observation. Through the slice analysis, a wealth of information reflecting the microstructure of the PCB (through holes, plating, etc.) can be obtained, which provides a good basis for the next step of quality improvement.

We provide high quality PCB Specimen Cutting Machine. If you have any requirements for our products, please feel free to contact us.